Stone Sand Making Machine

Stone Sand Making Machine

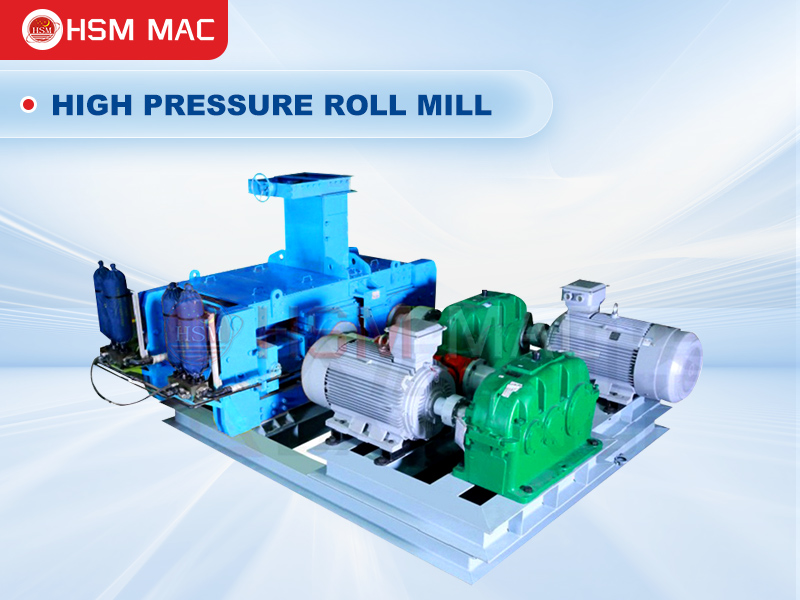

Stone sand making machine is also called gravel sand making machine, also called double roll sand making machine, double roll crusher, double roll machine

- Application:River pebbles, calcite, quartz, marble, cobblestone, bentonite, iron ore, bluestone, mountain stone, slag, limestone, weathered sand, diabase, granite, basalt, etc.

- Max feeding size: 25-100mm

- Output size: 0-5mm

- Capacity:2-400t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Stone sand making machine is also called gravel sand making machine, also called double-roll sand making machine, double-roll crusher, double-roll machine, double-roll crusher. It uses two motors to drive two pairs of rollers to squeeze and grind the materials. The crushed materials have better effects than general crushing machinery. It can crush various stones with compressive strength less than 160 MPa. It has the characteristics of low maintenance cost, low water consumption, stable performance, low power consumption, less dust and low noise. The demand for sand and gravel aggregates has increased significantly, which has led to the development of artificial sand making. Using stone sand making machine for sand making can provide finished products of different sizes to meet market demand.

Related Products

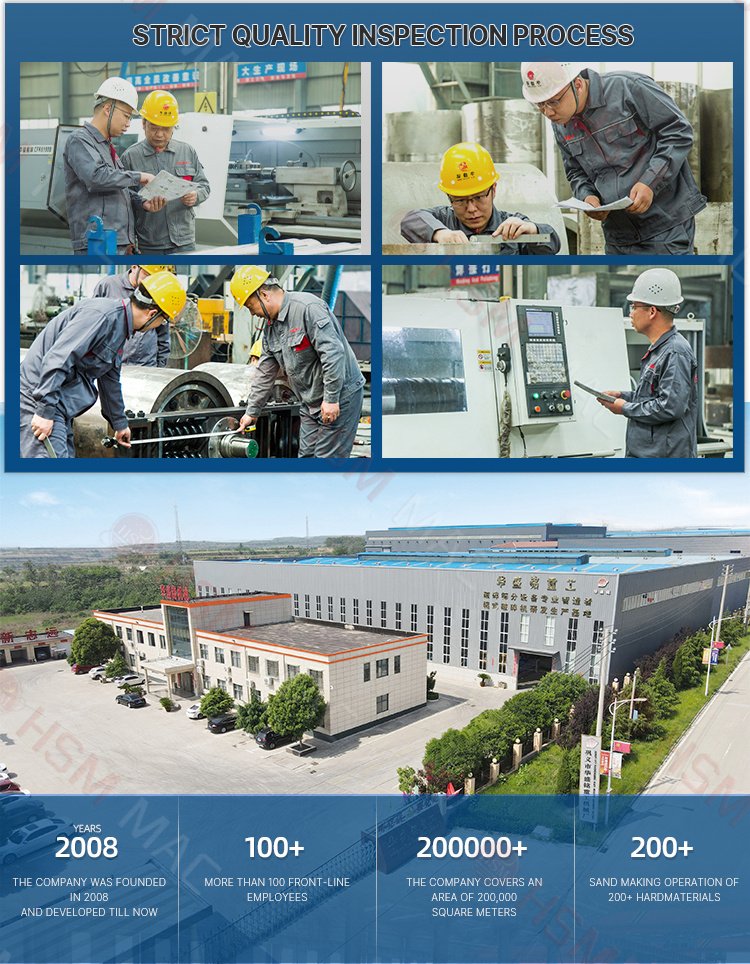

Why choose Huashengming

1. Stone sand making machine is better than hammer sand making machine, and there is no need to replace wearing parts.

2. The sand has full grain shape, reasonable grading, low over-crushing rate and high output.

3. Stone sand making machine has huge advantages over hammer crusher and impact crusher, and the average service life of roller sleeve is more than 2 years.

4. Huashengming high chromium manganese steel wear-resistant material contains rare metal roller skin material, which is wear-resistant, durable and high temperature resistant, and the discharge particle size of 1-3mm can be adjusted at will.

Related Products

Spring Roll Crusher four roller crusher

The stone sand making machine uses two sets of independently driven rollers to generate squeezing and shearing forces to crush materials through relative rotation. The materials fall between the two rollers through the feeding port, and the finished products fall naturally after being squeezed and crushed by the rollers. When encountering hard or unbreakable materials, the rollers can automatically give way by the action of hydraulic cylinders or springs, so that the gap between the two rollers increases, and the hard or unbreakable materials fall naturally, so as to ensure that the machine is not damaged. The two rollers rotating in opposite directions can adjust the pressure of the hydraulic cylinder or spring to control the output particle size of the product.

Specification and model | Roll diameter (mm) | Feed size (mm) | Productive capacity (t/h) |

2PGT400×250 | φ400 | ≤25 | 2-10 |

2PGT400×400 | φ400 | ≤25 | 5-12 |

2PGT610×400 | φ610 | ≤30 | 5-20 |

2PGT750×500 | φ750 | ≤30 | 10-40 |

2PGT800×600 | φ800 | ≤40 | 12-50 |

2PGY800×800 | φ800 | ≤40 | 40-50 |

| 2PGY800×1000 | φ800 | ≤40 | 50-80 |

2PGY1000×800 | φ1000 | ≤40 | 50-80 |

2PGY1000×1000 | φ1000 | ≤40 | 80-100 |

2PGY1200×1000 | φ1200 | ≤60 | 100-120 |

2PGY1200×1200 | φ1200 | ≤60 | 120-150 |

2PGY1500×1000 | φ1500 | ≤80 | 150-200 |

2PGY1500×1200 | φ1500 | ≤80 | 200-250 |

2PGY1800×1000 | φ1800 | ≤100 | 250-300 |

2PGY2000×1200 | φ2000 | ≤120 | 300-400 |