Ball Mill

Ball Mill

Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material

- Application:Cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics etc.

- Max feeding size: 25 mm

- Output size: 0.074-0.4 mm

- Capacity:0.5-130 t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics etc, it can grind various ores and other materials with dry type and wet type.

Features:

1. Wide scope of application, simple structure and easy maintenance.

2. Big processing capacity, the advantages of continuous operation is obvious.

3. Cylinder liner and grinding media can use a variety of materials, corrosion resistance is strong, and use is wide.

4. Convenient installation and commissioning, easy to operate.

5. Productivity is high; the cost of use is low.

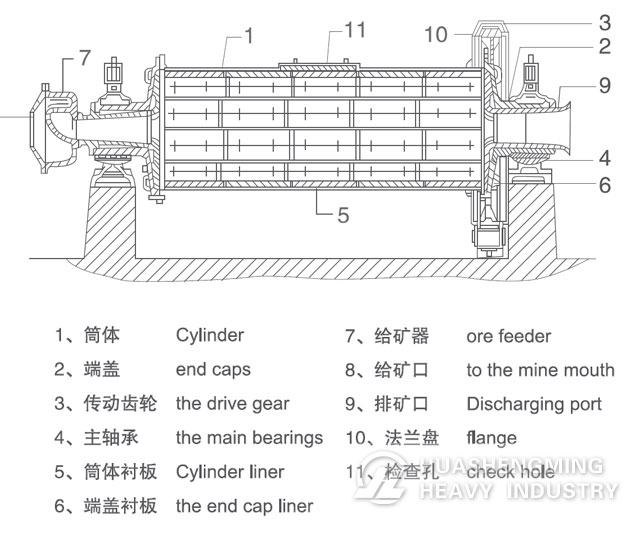

Structures:

This ball mill is made up of feeder part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control) etc. main part. Hollow shaft adopt steel casting, lining can be converted, big rotating gear processed by casting gear hobbling .In the barrel there are board of wear-resistant, have a good characteristics of wear-resisting. The machine is of steady operating and reliable working.

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Model | Cylinder Speed | Ball Charge | Feed Particle | Discharge | Output | Motor Power | Weight |

900*1800 | 38 | 1.5 | <=20 | 0.075- 0.89 | 0.65 - 2 | 18.5 | 3.6 |

900*2100 | 38 | 1.3-1.4 | <=15 | 0.075- 0.83 | 0.7 - 3.5 | 18.5 | 3.9 |

900*3000 | 38 | 2.7 | <=20 | 0.075- 0.89 | 1.1 - 3.5 | 22 | 4.5 |

1200*2400 | 32 | 3.8 | <=25 | 0.075 - 0.6 | 1.5 - 4.8 | 30 | 11.5 |

1200*2800 | 32 | 3.3-3.5 | <=25 | 0.075 - 0.6 | 2 - 6 | 30 | 13 |

1200*4500 | 32 | 7 | <=25 | 0.074 - 0.4 | 1.6 - 5.8 | 45 | 13.8 |

1500*3000 | 27 | 8 | <=25 | 0.074 - 0.4 | 2 - 5 | 75 | 17 |

1500*3500 | 27 | 6.75-6.4 | <=25 | 0.075 - 0.4 | 3 - 7 | 75 | 17.5 |

1500*4500 | 27 | 14 | <=25 | 0.074 - 0.4 | 3.5 - 12 | 110 | 21 |

1500*5700 | 27 | 15 | <=25 | 0.074 - 0.4 | 3.5 - 8 | 115 | 24.7 |

1830*3000 | 24 | 18 | <=25 | 0.074 - 0.4 | 4 - 10 | 130 | 28 |

1830*3600 | 24 | 10.6-11.35 | <=25 | 0.075 - 0.4 | 5 - 22 | 130 | 33.5 |

1830*7000 | 24 | 25 | <=25 | 0.074 - 0.4 | 7.5 - 17 | 210 | 36 |

2100*3600 | 22 | 14-15.2 | <=25 | 0.075 - 0.4 | 15 - 36 | 370 | 46.8 |

2200*5500 | 21 | 30 | <=25 | 0.074 - 0.4 | 10 - 22 | 210 | 48.5 |

2200*6500 | 21 | 31 | <=25 | 0.074 - 0.4 | 14 - 26 | 380 | 52.8 |

2200*7500 | 21 | 33 | <=25 | 0.074 - 0.4 | 16 - 29 | 380 | 56 |

2400*3000 | 20.6 | 15.5-16.6 | <=25 | 0.075 - 0.4 | 22 - 24 | 245 | 59 |

2400*4500 | 21 | 30 | <=25 | 0.074 - 0.4 | 8.5 - 60 | 380 | 65 |

2700*3600 | 20.6 | 39 | <=25 | 0.074 - 0.4 | 12 - 70 | 400 | 91.3 |

2700*4000 | 20.7 | 40 | <=25 | 0.074 - 0.4 | 12 - 80 | 400 | 94 |

2700*4500 | 20.7 | 48 | <=25 | 0.074 - 0.4 | 12 - 90 | 430 | 102 |

3200*4500 | 18 | 65 | <=25 | 0.075 - 0.4 | 25-130 | 800 | 137 |