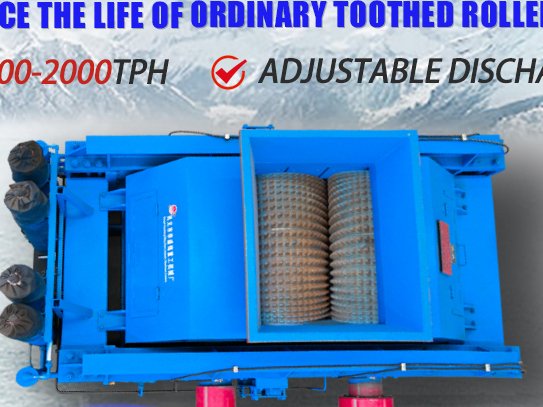

Toothed Roller Crusher

Toothed Roller Crusher

Toothed roller crusher is mainly used for crushing rocks of medium or lower rigidity, such as coking coal, aggregate, limestone, soil, asphalt, glass, brick, shale and so on.

- Application:Coal, metallurgy, mine, chemical , building material industry etc.

- Max feeding size: 1050 mm

- Output size: 15-200 mm

- Capacity:5-300 t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Toothed roller crusher is mainly used for crushing rocks of medium or lower rigidity, such as coking coal, aggregate, limestone, soil, asphalt, glass, brick, shale and so on.

Features:

1.Low wear parts, only toothed roller skin,we get the patent of our roller skin, the material is high manganese steel with tungsten, tin, chromium and other rare metals. Very wear-resistant and high temperature resistant;

2. Compact structure, lower noise and efficiency;

3. Pressure and particle size are adjustable easily;

4. Self-protection, the parts can not be damaged when hard materials such as the metalsgoes into the crushing cavity;

5. Good performance, low cost in operation and easily maintenance.

1. The fixed roller and movable roller are driven by the motor via reducer and v-belt.

2. The raw materials fall into the part between the two rollers from inlet of the machine.

3.The two rollers rotates inward simultaneously, the materials are extruded, crushed and ground, then the end products come out from the bottom of this crusher.

Model | Roller | Roller | Max feeding | Discharging | Capacity | Motor | Weight | Dimension |

450×500 | 450 | 500 | 200-500 | 15-100 | 30-60 | 7.5×2 | 3800 | 2260×2200×766 |

600×750 | 600 | 750 | 300-600 | 20-120 | 60-100 | 11×2 | 7200 | 2780×3065×1310 |

600×900 | 600 | 900 | 300-600 | 30-150 | 80-120 | 18.5×2 | 7800 | 4500×1900×1350 |

800×1050 | 800 | 1050 | 500-800 | 30-150 | 100-160 | 22×2 | 12600 | 2550×2050×1100 |

900×900 | 900 | 900 | 600-900 | 30-200 | 150-200 | 22×2 | 13500 | 2780×4100×1550 |

1015×760 | 1015 | 760 | 700-950 | 30-200 | 150-200 | 45×2 | 18800 | 7800×3200×1980 |

1200×1500 | 1200 | 1500 | 800-1050 | 30-200 | 200-300 | 55×2 | 52000 | 8010×4500×2050 |