Sizing Teeth Roller Crusher

Sizing Teeth Roller Crusher

Sizing teeth roller crusher is used for crushing material from 50-1500mm to 15-300mm, capacity can reach 80-3000t/h. Crushing Strength: <200mpa.

- Application:Coal, construction material, industrial material, mixed/medium strength ores etc.

- Max feeding size: 50-1500 mm

- Output size: 15-300 mm

- Capacity:80-3000 t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Sizing teeth roller crusher is used for crushing material from 50-1500mm to 15-300mm, capacity can reach 80-3000t/h. Crushing Strength: <200mpa.Coal: Raw coal with rock and clean coal sizing.Construction Materials: Limestone, Gypsum, Marl, Clay Industrial Materials: Borax, Chalk, Kimberlite, Oil Sands Mixed/Medium Strength Ores: Gold, Nickel, Silver, Copper Miscellaneous: Overburden, Coke, Carbon Anodes.

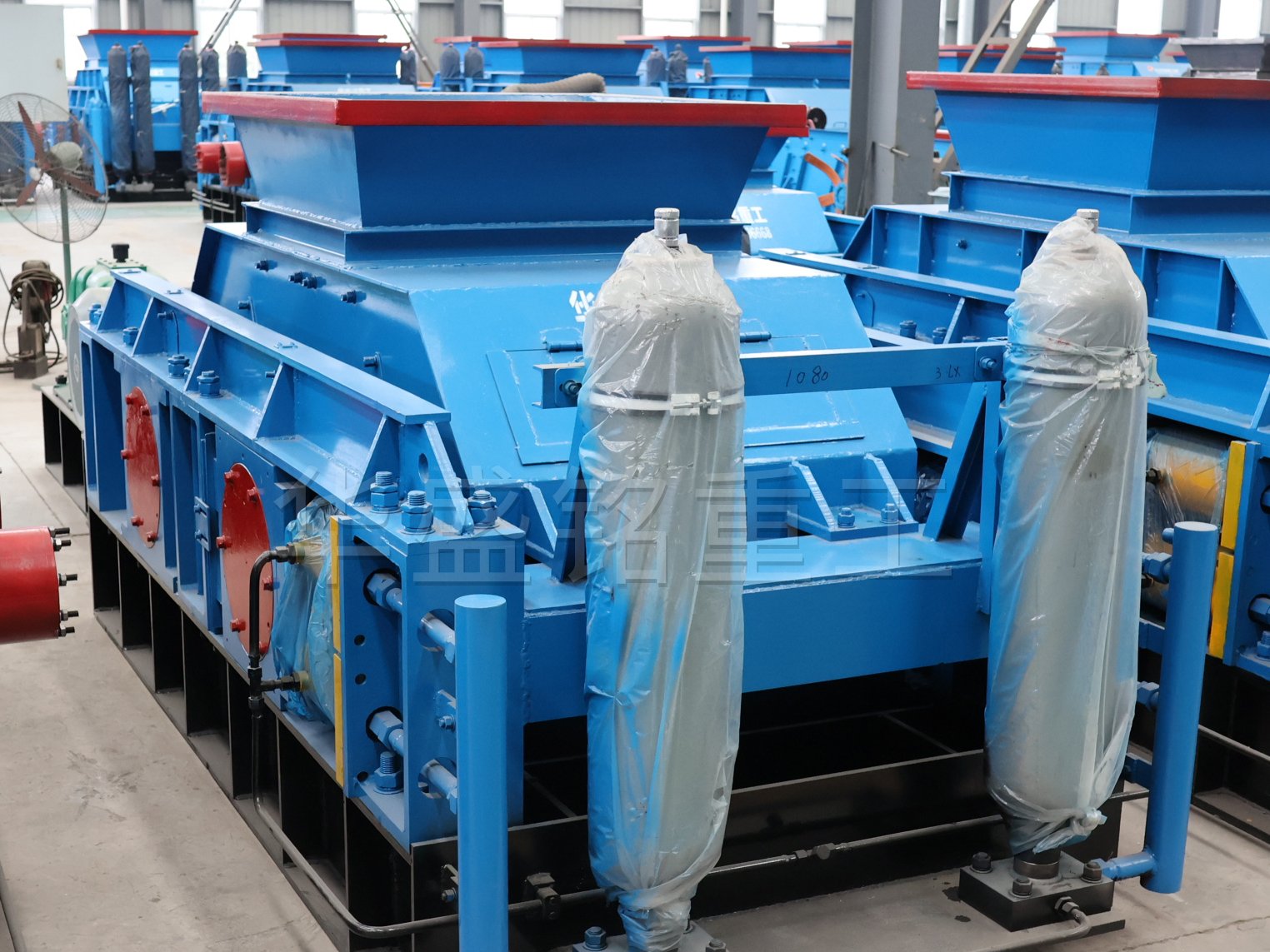

Features:

1. Correctly control product particles

2. Has no over crushing problem.

3. Very low wear of teeth roller and energy consuming.

4. Double efficacy: screening and crushing

5. Simple structure, low height of complete machine, small operation vibration.

6. Adjustable width between centers

7. Crushing tooth is high intensity and high wearing. (for crushing coal it can be weld buildup or changes at job site and the working life will not lower than 6000 hours).

8. Large processing capacity, less noise level and small quantity of dust.

9. Has self cleaning set-up, avoid non-choking of sticky material.

10. Intelligent lubrication system.

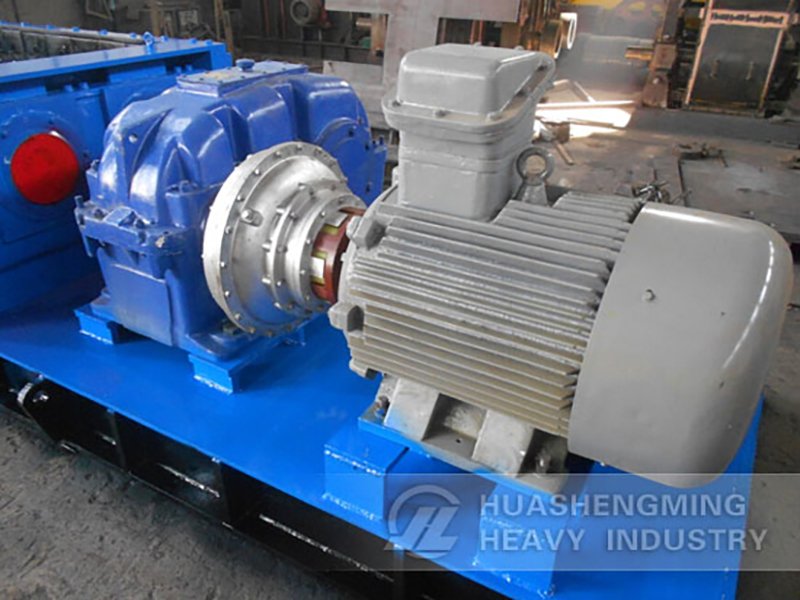

Structures:

The structure of HSM Sizing Teeth Roller Crusher make the output material powder percent very low.

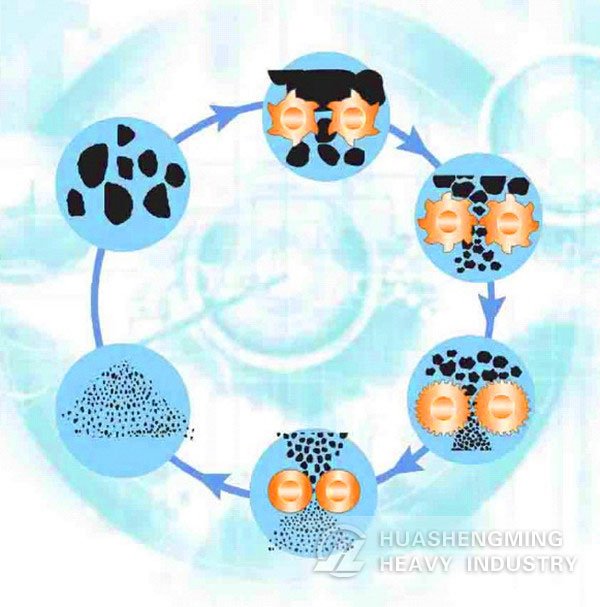

According to the optimum design of crushing tooth shape and tooth layout, the two rollers relative rotation as a grizzly. So as to make the material which size is bigger than request will be crushed and material which meet the size need will be directly pass through. Discharging sizes to be block shape, less fine power, low energy consume.

1.material be feed to our crusher machine and begin first screening-screen the material which size no need be broken .

2. the material can’t past the teeth roller will be broken to small size.

3. material finish break and get the finished products you need.

140 Series Sizing Teeth Roller Crusher For Coarse Crushing | ||||||

Model Specification | 2PLF-140/150 | 2PLF-140/200 | 2PLF-140/250 | 2PLF-140/300 | ||

Inlet Size(mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ||

Discharge Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 | ||

Capacity(t/h) | 1300-2500 | 1700-3800 | 2200-4600 | 2700-5500 | ||

Single Driven Type Motor Power(kw) | 315-355 | 355-450 | 400-560 | 450-630 | ||

Dual Driven Type Motor Power(kw) | 2×(185-280) | 2×(200-315) | 2×(220-355) | 2×(250-400) | ||

120 Series Sizing Teeth Roller Crusher For Coarse Crushing | ||||||

Model Specification | 2PLF-120/150 | 2PLF-120/200 | 2PLF-120/250 | 2PLF-120/300 | ||

Inlet Size(mm) | ≤1200 | ≤1200 | ≤1200 | ≤1200 | ||

Discharge Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 | ||

Capacity(t/h) | ≤1500 | ≤2000 | ≤2700 | ≤3300 | ||

Single Driven Type Motor Power(kw) | 315-355 | 355-450 | 450-560 | 560-630 | ||

Dual Driven Type Motor Power(kw) | 2×(132-185) | 2×(160-220) | 2×(185-250) | 2×(200-315) | ||

100 Series Sizing Teeth Roller Crusher For Coarse Crushing | ||||||

Model Specification | 2PLF-100/160 | 2PLF-100/200 | 2PLF-100/250 | |||

Inlet Size(mm) | ≤700 | ≤700 | ≤700 | |||

Discharge Size(mm) | 50-150 | 50-150 | 50-150 | |||

Capacity(t/h) | 280-850 | 350-1000 | 500-1500 | |||

Single Driven Type Motor Power(kw) | 160-200 | 160-250 | 200-315 | |||

Dual Driven Type Motor Power(kw) | 2×(90-132) | 2×(110-160) | 2×(132-200) | |||

80 Series Sizing Teeth Roller Crusher For Medium Crushing | ||||||

Model Specification | 2PLF-80/150 | 2PLF-80/200 | 2PLF-80/250 | 2PLF-80/300 | ||

Inlet Size(mm) | ≤550 | ≤550 | ≤550 | ≤550 | ||

Discharge Size(mm) | 50-150 | 50-150 | 50-150 | 50-150 | ||

Capacity(t/h) | 200-600 | 260-750 | 300-1000 | 400-1150 | ||

Single Driven Type Motor Power(kw) | 132-160 | 160-200 | 185-250 | 250-280 | ||

Dual Driven Type Motor Power(kw) | 2×(75-90) | 2×(90-132) | 2×(110-185) | 2×(132-220) | ||

50 Series Sizing Teeth Roller Crusher For Fine Crushing | ||||||

Model Specification | 2PLF-50/60 | 2PLF-50/120 | 2PLF-50/150 | 2PLF-50/200 | ||

Inlet Size(mm) | ≤300 | ≤300 | ≤300 | ≤300 | ||

Discharge Size(mm) | 50-150 | 50-150 | 350-150 | 50-150 | ||

Capacity(t/h) | 80-240 | 200-600 | 250-700 | 300-800 | ||

Single Driven Type Motor Power(kw) | 37 | 75 | 90 | 160 | ||

Dual Driven Type Motor Power(kw) | 2×18.5 | 2×37 | 2×45 | 2×75 | ||