Granite Sand Making Machine

Granite Sand Making Machine

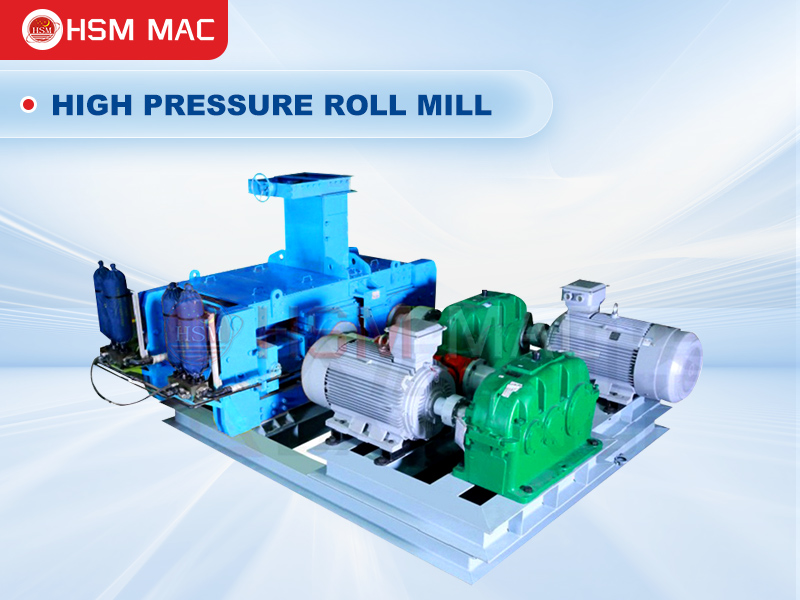

Stone sand making machine is also called gravel sand making machine, also called double roll sand making machine, double roll crusher, double roll machine

- Application:Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

- Max feeding size: 25-100mm

- Output size: 0-5mm

- Capacity:2-400t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Introduction: Embrace Eco-Friendly Sand Production

Granite sand making machine plays a vital role in sustainable construction. With Huashengming's double roller crusher, you achieve high-quality sand production while reducing environmental impact. This cutting-edge machine is perfect for turning hard granite into premium sand with minimal waste.

Efficiency Meets Sustainability

Huashengming’s double roller crusher ensures maximum efficiency during granite sand production. It quickly processes large granite pieces into fine sand with precision. Its energy-efficient design reduces power consumption, significantly lowering operational costs. By using less energy, this machine promotes sustainability without compromising on performance.

Advanced Features for Customization

The machine offers adjustable settings to control the sand particle size. Whether your project requires coarse or fine sand, you can tailor the output to your needs. Additionally, its high crushing ratio ensures consistent quality and reduces material waste. These features make it a versatile choice for diverse construction requirements.

Low Environmental Impact

Huashengming’s double roller crusher minimizes noise and dust production, making it an eco-friendly option. Its innovative design ensures compliance with environmental standards while maintaining workplace safety. For companies prioritizing green practices, this machine is a reliable solution.

Durability and Easy Maintenance

This granite sand making machine is built for durability. Its high-strength alloy steel rollers withstand the toughest materials, ensuring a long service life. Maintenance is simple, thanks to its user-friendly design, allowing you to reduce downtime and keep operations running smoothly.

Conclusion: Build Sustainably with Huashengming

Investing in Huashengming’s granite sand making machine guarantees superior sand production and eco-friendly practices. With its advanced features and reliable performance, you can streamline operations while minimizing your environmental footprint. Choose Huashengming’s double roller crusher for your sustainable construction needs today.

The machine’ s gap between two rollers can be adjusted freely between 1mm-20mm. After the roller’ s gap is predetermined, the crushing grain size can be controlled reliably, and all of it is discharged from the lower part of the crushing chamber with ideal grain size.

Specification and model | Roll diameter (mm) | Feed size (mm) | Productive capacity (t/h) |

2PGT400×250 | φ400 | ≤25 | 2-10 |

2PGT400×400 | φ400 | ≤25 | 5-12 |

2PGT610×400 | φ610 | ≤30 | 5-20 |

2PGT750×500 | φ750 | ≤30 | 10-40 |

2PGT800×600 | φ800 | ≤40 | 12-50 |

2PGY800×800 | φ800 | ≤40 | 40-50 |

| 2PGY800×1000 | φ800 | ≤40 | 50-80 |

2PGY1000×800 | φ1000 | ≤40 | 50-80 |

2PGY1000×1000 | φ1000 | ≤40 | 80-100 |

2PGY1200×1000 | φ1200 | ≤60 | 100-120 |

2PGY1200×1200 | φ1200 | ≤60 | 120-150 |

2PGY1500×1000 | φ1500 | ≤80 | 150-200 |

2PGY1500×1200 | φ1500 | ≤80 | 200-250 |

2PGY1800×1000 | φ1800 | ≤100 | 250-300 |

2PGY2000×1200 | φ2000 | ≤120 | 300-400 |