Gold ore sand making machine

Gold ore sand making machine

Gold ore sand making machine

- Application:Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

- Max feeding size: 25-100mm

- Output size: 0-5mm

- Capacity:2-400t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

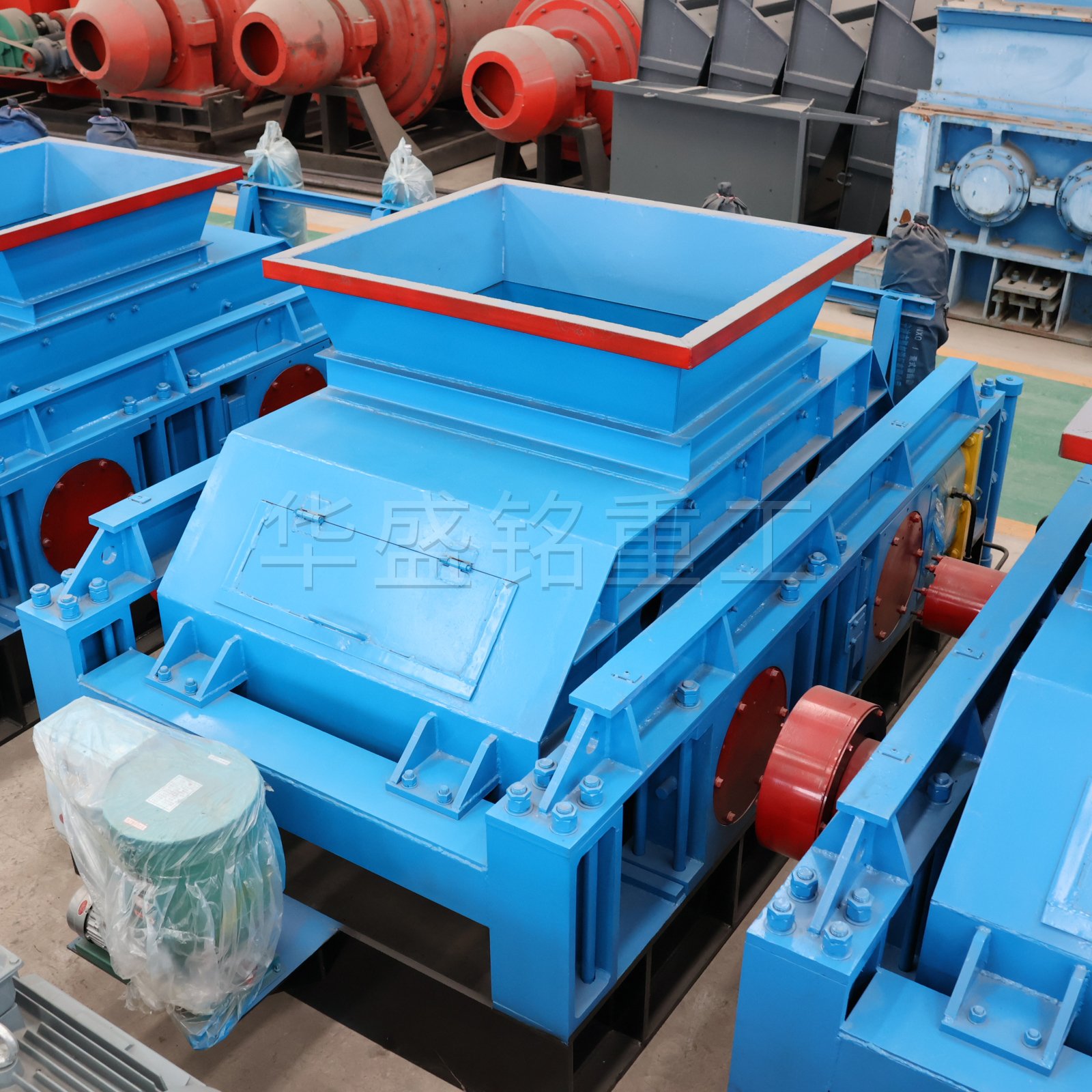

Gold ore is a metal ore with high industrial utilization value. As the value of gold continues to increase, the gold ore processing industry has also developed rapidly. The appearance and structure of gold ore sand making machine is roughly the same as that of traditional sand making machine. The difference is that this equipment adopts new hydraulic, computer control and other technologies. It runs more smoothly and has higher output than sand making equipment of similar specifications. For this reason, this equipment has become a popular equipment among many sand making equipment. At present, there are a large number of gold ore sand making machines on the market. Among them, the gold ore sand making machine with better application effect and high sales volume belongs to the gold ore double roller sand making machine of Huashengming Heavy Industry.

Why choose Huashengming

1. Gold ore sand making machine is better than hammer sand making machine, and there is no need to replace wearing parts.

2. The sand has full grain shape, reasonable gradation, low over-crushing rate and high output.

3 Calcite sand making machine has huge advantages over hammer crusher and impact crusher, and the average service life of roller sleeve is more than 2 years.

4. Huashengming high chromium manganese steel wear-resistant material contains rare metal roller skin, which has applied for national patent. The discharge particle size can be accurately adjusted, which has applied for national patent. The gold ore sand making machine roller has applied for national patent.

Applicable materials

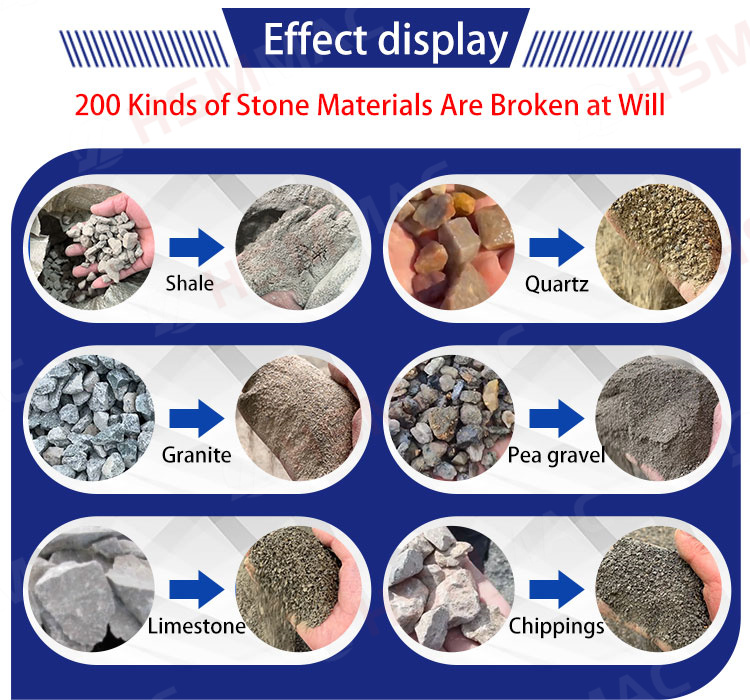

Crushing and sand making of river pebbles, calcite, quartz, glass, marble, pebbles, bentonite, iron ore, bluestone, mountain stone, limestone, weathered sand, diabase, granite, basalt and other materials.

Gold ore sand making machine uses rollers for crushing. The material enters between the rollers from the feed port and crushes the river pebbles through the extrusion. There is a certain gap between the two rollers. The larger the gap between the two rollers, the larger the material size. Under the action of the compression spring, the smaller the gap between the two rollers, the smaller the material size. By changing the gap, the material size can be controlled.

规格型号 | 辊体直径 | Feed size | production |

2PGT400x250 | φ400 | ≤25 | 2-10 |

2PGT400x400 | φ400 | ≤25 | 5-12 |

2PGT610x400 | φ610 | ≤30 | 5-20 |

2PGT750x500 | φ750 | ≤30 | 10-40 |

2PGT800x600 | φ800 | ≤40 | 12-50 |

2PGY800x800 | φ800 | ≤40 | 40-50 |

2PGY800x1000 | φ800 | ≤40 | 50-80 |

2PGY1000x800 | φ1000 | ≤40 | 50-80 |

2PGY1000x1000 | φ1000 | ≤40 | 80-100 |

2PGY1200x1000 | φ1200 | ≤60 | 100-120 |

2PGY1200x1200 | φ1200 | ≤60 | 120-150 |

2PGY1500x1000 | φ1500 | ≤80 | 150-200 |

2PGY1500x1200 | φ1500 | ≤80 | 200-250 |

2PGY1800x1000 | φ1800 | ≤100 | 250-300 |

2PGY2000x1200 | φ2000 | ≤120 | 300-400 |