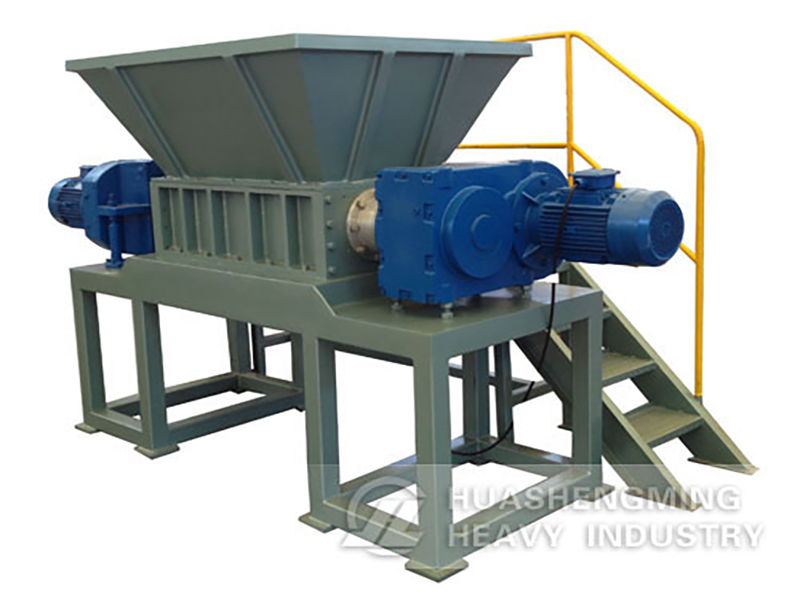

Four Roller Crusher

Four Roller Crusher

- Application:

- Max feeding size:

- Output size:

- Capacity:

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Four Roller Crusher is a kind of medium and fine crushing machine of simple structure, reliable performance.

Four Roll Crusher is mainly used in medium hardness materials such as limestone, clay shale, brick, slag, clinker, feldspar, coke, coal, steel slag etc.

Features:

1. High efficiency, good performance, simple structure, low noise.

2. Easy maintenance. the rollers' surface adopts anti-abrasive welding rod or exchangeable dental plate, the maintenance is simple.

3. Low cost and high efficiency, in addition to roller skin, no wearing parts.

4. Four roller crusher gives a very fine product size distribution and produces very little dust or fines.

1. Four roller crusher is fixed with four high-strength resistant grinding rollers.

2. Four rollers relative rotation generates high extrusion pressure and shear force for crushing the material.

3. Firstly the material enters into the space between the topside two rollers. Here, it is extruded, rolled and sheared (coarse crushing) by the the topside two rotation rollers.

4. Secondly the material extruded and milled (fine crushing) by the bottom two rolls which are relatively rotating. under the extrusion, cut and mill of the bottom two rolls, the material becomes the required size , sent by the transport equipment.

Model | Feeding | Discharging | Capacity | Motor Power | Protection Mode | Transmission Mode | |

4PG0404PT | <20 | 0.1-10 | 2-30 | 7.5(11) | 11(15) | Spring | Coupling or |

4PG0605PT | <40 | 0.1-15 | 5-60 | 22(30) | 30(37) | ||

4PG0806PT | <40 | 0.1-20 | 8-90 | 30(37) | 37(45) | ||

4PG0809PT(Y) | <60 | 0.1-20 | 12-120 | 37(45) | 45(55) | Spring or | |

4PG0812PT(Y) | <60 | 0.1-20 | 20-180 | 45(55) | 55(75) | ||

4PG1012PT(Y) | <80 | 0.1-30 | 30-220 | 55(75) | 75(90) | ||

4PG1212PT(Y) | <90 | 0.1-40 | 45-320 | 75(90) | 90(110) | ||

4PG1216PT(Y) | <90 | 0.1-50 | 55-400 | 90(110) | 110(132) | ||

4PG1218PT(Y) | <90 | 0.1-50 | 70-500 | 110(132) | 132(160) | ||