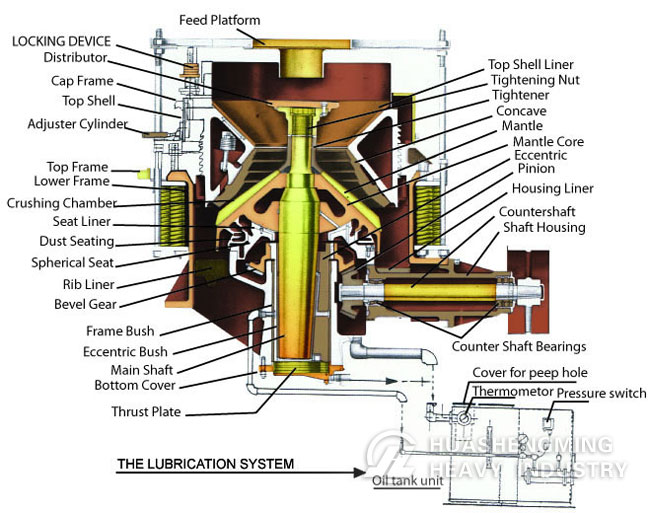

Spring Cone Crusher

Spring Cone Crusher

When spring cone crusher begins to work, the electric motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the r

- Application:Hard and mid-hard rocks and ores like iron ore, copper, limestone,quartz and granite etc.

- Max feeding size: 310 mm

- Output size: 5-60 mm

- Capacity:15-340 t/h

- Delivery:5-15 days

- Shipment: Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Adopting the latest technological development, PYB Series spring cone crusher is suitable for hard and mid-hard rocks and ores like iron ore, copper, limestone, quartz and granite, etc. PYB Series spring cone crushers are the ultimate solution for the secondary crushing to achieve uniform product size of hard rocks, ores and minerals.

Features:

1)Trustworthy insurance system

The spring insurance system applied in this machine can adjust the size of discharge opening to make sure that crusher works safely.

2)Adjustable crushing chamber

The shape of crushing chamber plays a very important role in the whole machine's performance. The Cone Crusher has four kinds of chamber shapes. Customers can choose the suitable one according to their specific demands.

3)Easy replacing of chamber

There is no need to fill the reverse side of crushing wall with anything when installing a new crushing wall. It is fixed by bolts, which not only decreases the difficulty of replacing, but also increases the speed.

4)Simple operation

The cone crusher employed high-pressure resistant displacement transducer. When the operator wants to adjust the size of the discharge opening, he only needs to press the button on the operation board. In addition, the operator can see the changing process of the size. So, it is extremely convenient and precise.

Spring Cone Crusher Structures:

When spring cone crusher begins to work, the electric motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall fixed on the adjusting sleeve, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

Model | Max.feeding | Width of | Processing | Motor | Swing frequency | Total | Dimensions | |

PYB | 600 | 65 | 12-25 | 40 | 30 | 356 | 5 | 2234×1370×1675 |

PYD | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

PYB | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 |

PYZ | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

PYD | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

PYB | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 |

PYZ | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

PYD | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

PYB | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910×2894×3809 |

PYZ | 185 | 10-30 | 115-320 | 50.3 | 3910×2894×3809 | |||

PYD | 85 | 5-13 | 75-230 | 50.2 | 3910×2894×3809 | |||

PYB | 2200 | 300 | 30-60 | 59-1000 | 280-260 | 220 | 80 | 4622×3302×4470 |

PYZ | 230 | 10-30 | 200-580 | 80 | 4622×3302×4470 | |||

PYD | 100 | 5-15 | 120-340 | 81.4 | 4622×3302×4470 | |||