recycled concrete sand making machine

recycled concrete sand making machine

Recycled Concrete Sand Making Machine: A Powerful Tool for Sustainable Construction

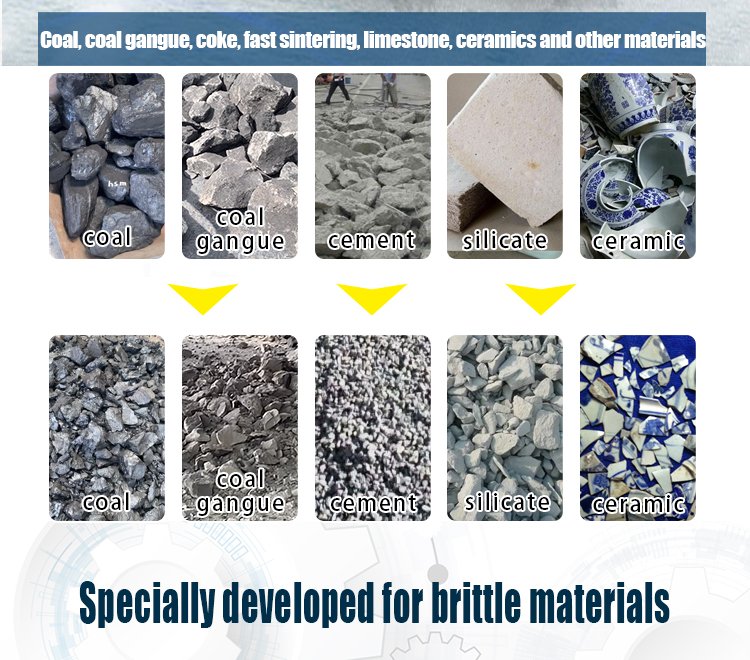

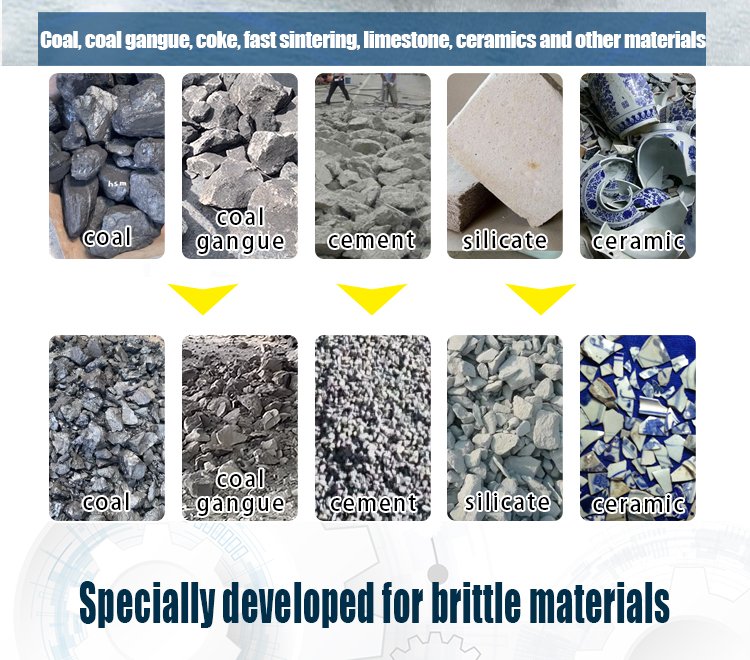

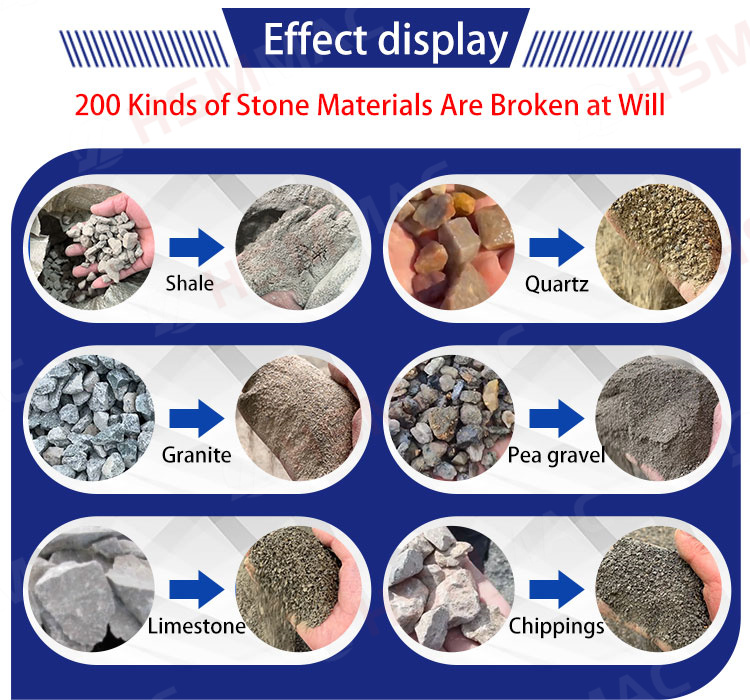

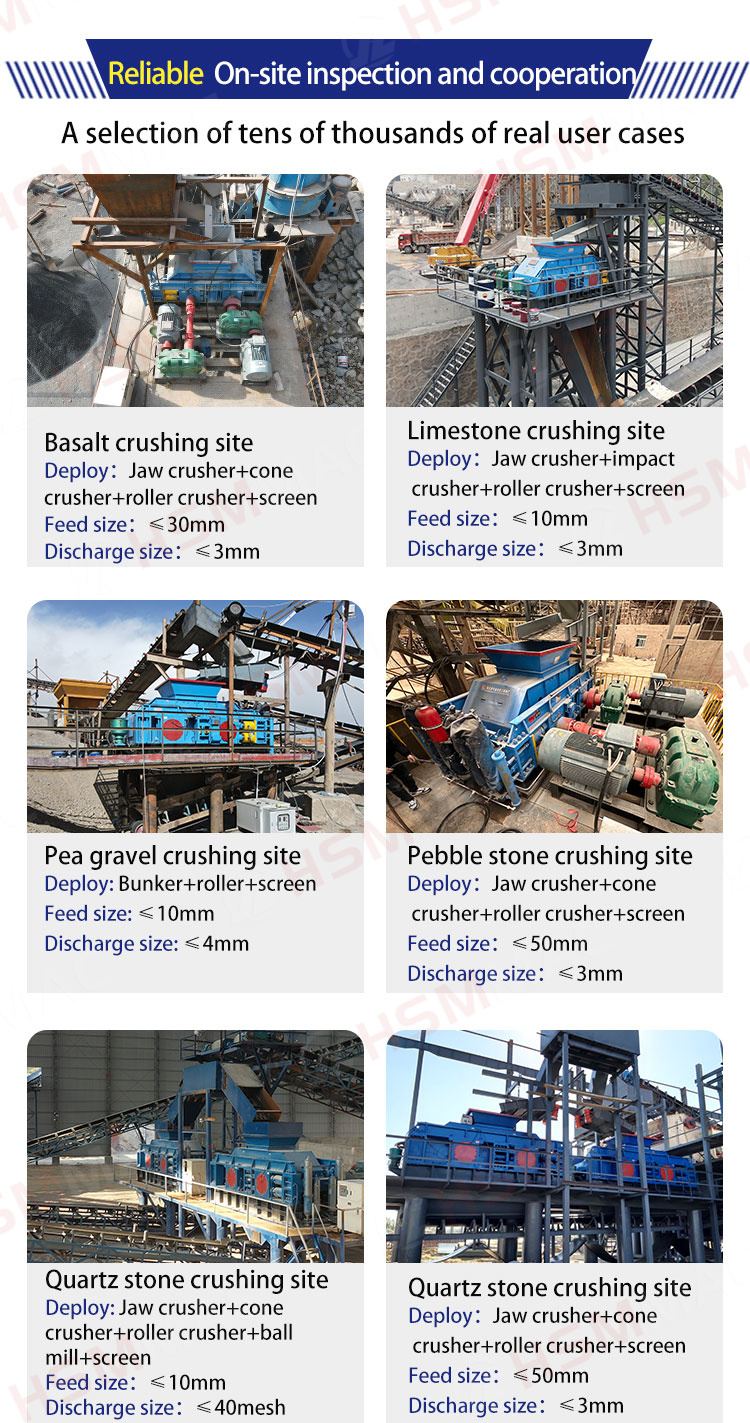

- Application:River pebbles, calcite, quartz, marble, cobblestone, bentonite, iron ore, bluestone, mountain stone, slag, limestone, weathered sand, diabase, granite, basalt, etc.

- Max feeding size: 25-100mm

- Output size: 0-5mm,10-25mm

- Capacity:2-400t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

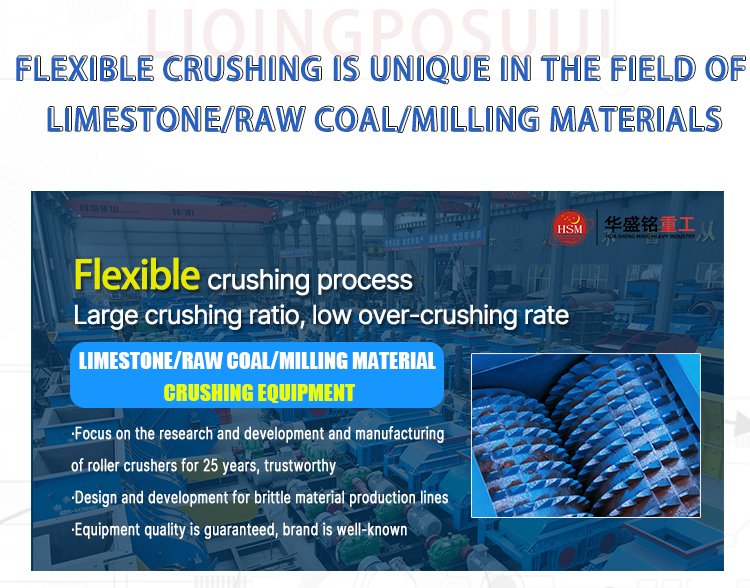

The demand for sustainable construction materials is on the rise. One key solution is recycled concrete sand, and a recycled concrete sand making machine plays a crucial role in this process. This machine transforms waste concrete into high-quality sand, offering a sustainable alternative to natural sand. Its efficiency and effectiveness make it an ideal choice for construction companies.

Why Choose a Recycled Concrete Sand Making Machine?

Recycling concrete has many benefits. It helps reduce construction waste, minimizes environmental impact, and conserves natural resources. A recycled concrete sand making machine makes this possible. It processes discarded concrete into fine sand, ready for reuse. This reduces the need for landfills and cuts down on new material extraction.

Moreover, using recycled sand lowers project costs. Construction companies can save money on raw materials while maintaining quality. This machine is perfect for companies aiming to balance profit and environmental responsibility.

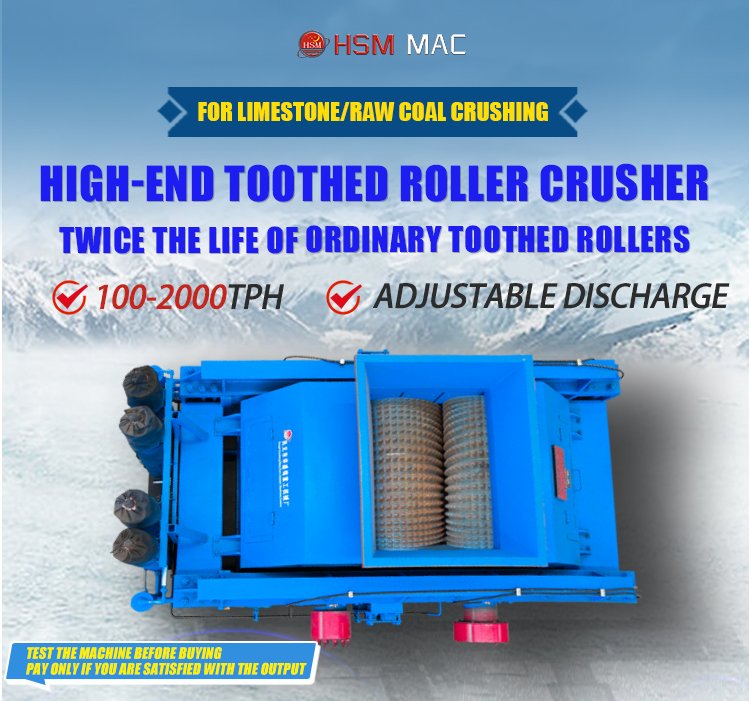

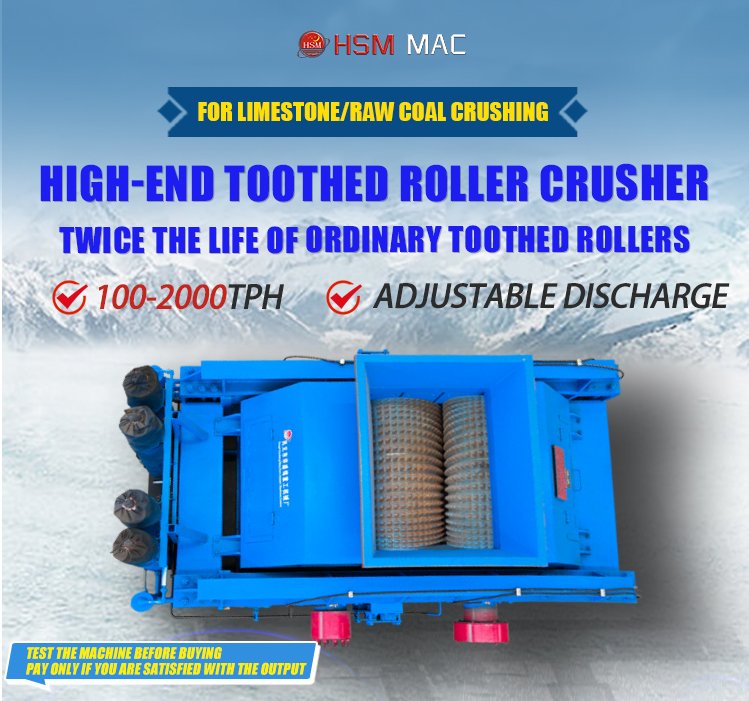

Key Features of the Recycled Concrete Sand Making Machine

This machine offers several key features:

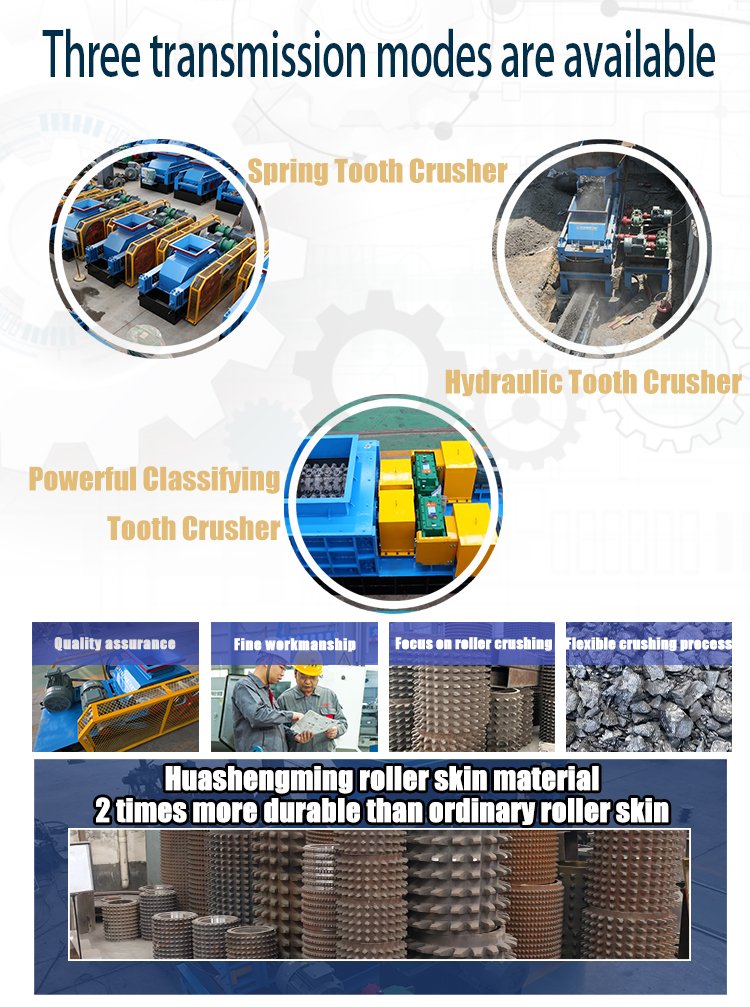

High Efficiency: The machine converts large concrete pieces into fine sand quickly. Its robust design ensures continuous operation.

Energy-Saving: It uses advanced technology to reduce power consumption. This feature lowers operational costs significantly.

Durable Design: Built with wear-resistant materials, the machine guarantees long-lasting performance. It handles high-pressure operations without frequent maintenance.

These features make the machine suitable for various construction projects, from road building to commercial developments.

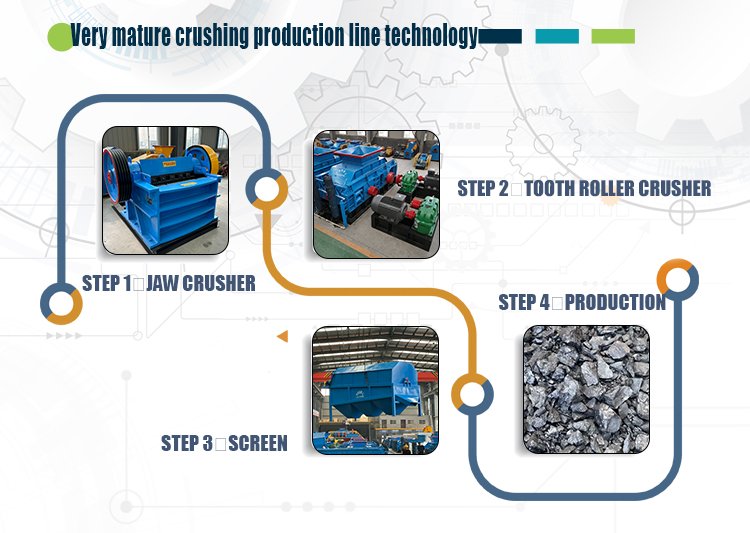

The working process of a recycled concrete sand making machine is simple but effective. First, operators feed broken concrete into the crusher. The machine then grinds the material into smaller particles. Next, it sorts the particles, separating sand-sized pieces from larger aggregates. Finally, the fine sand is ready for use in new construction projects.

This process is seamless, and the output is consistent. With a well-designed machine, users get high-quality recycled sand every time. It is a straightforward solution for turning waste into a valuable resource.

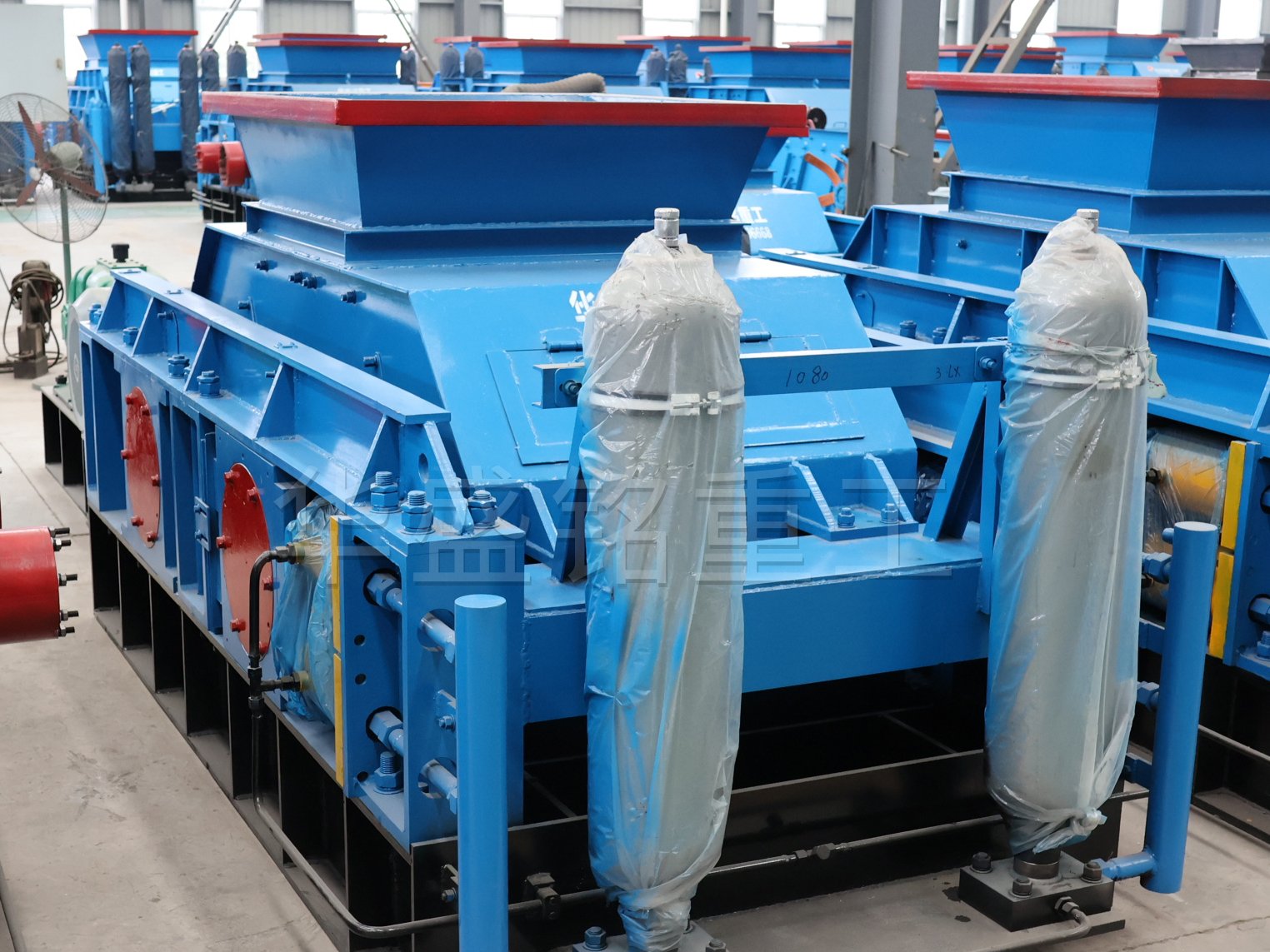

| Model | Roller diameter (mm) | Roller length (mm) | Max feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Motor power (kw) | Weight (kg) | Dimension (L×W×H) |

| 450×500 | 450 | 500 | 200-500 | 15-100 | 30-60 | 7.5×2 | 3800 | 2260×2200×766 |

| 600×750 | 600 | 750 | 300-600 | 20-120 | 60-100 | 11×2 | 7200 | 2780×3065×1310 |

| 600×900 | 600 | 900 | 300-600 | 30-150 | 80-120 | 18.5×2 | 7800 | 4500×1900×1350 |

| 800×1050 | 800 | 1050 | 500-800 | 30-150 | 100-160 | 22×2 | 12600 | 2550×2050×1100 |

| 900×900 | 900 | 900 | 600-900 | 30-200 | 150-200 | 22×2 | 13500 | 2780×4100×1550 |

| 1015×760 | 1015 | 760 | 700-950 | 30-200 | 150-200 | 45×2 | 18800 | 7800×3200×1980 |

| 1200×1500 | 1200 | 1500 | 800-1050 | 30-200 | 200-300 | 55×2 | 52000 | 8010×4500×2050 |