Hydraulic roller sand making machine

Hydraulic roller sand making machine

Hydraulic roller sand making machine

- Application:Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

- Max feeding size: 25-100mm

- Output size: 0-5mm

- Capacity:2-400t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Hydraulic Roller Sand Making Machine – The Ideal Choice for High-Efficiency Sand Production

The Hydraulic Roller Sand Making Machine provides a powerful solution for efficient sand production. Its hydraulic system enhances performance, producing consistent, high-quality sand with minimal energy use. This machine is perfect for quarries, construction sites, and various large-scale projects.

1. Hydraulic System Ensures Precision and Control

First, the hydraulic system enables precise control over the crushing force. Operators can easily adjust the force to produce uniform sand. This flexibility is ideal for projects requiring specific sand textures.

2. High Efficiency Lowers Production Costs

Additionally, the machine’s high efficiency reduces production costs. The hydraulic system minimizes energy consumption, leading to lower operational expenses. As a result, it offers significant savings in both time and money.

3. Durable Rollers Increase Equipment Longevity

Furthermore, durable rollers enhance the machine’s lifespan. These rollers withstand heavy-duty crushing tasks without frequent maintenance. Consequently, the machine performs reliably over long periods, maximizing return on investment.

4. Minimal Downtime Boosts Productivity

Another key advantage is the machine’s minimal downtime. The hydraulic system allows quick adjustments and smooth operation. Therefore, users experience fewer delays, boosting overall productivity on-site.

5. Versatile Applications Across Various Projects

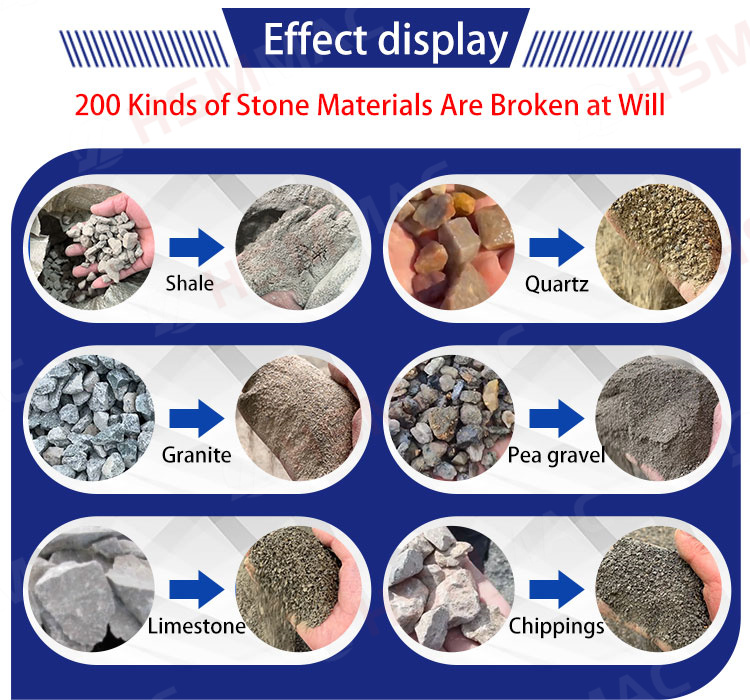

Finally, the machine’s versatility suits multiple applications. Whether for limestone, granite, or cobblestone, it efficiently processes diverse materials. This adaptability makes it a valuable asset across many sand-making projects.

In summary, the Hydraulic Roller Sand Making Machine offers an optimal solution for high-efficiency sand production. With precise control, low costs, durability, and versatility, this machine remains a top choice for industrial sand-making needs.

The machine’ s gap between two rollers can be adjusted freely between 1mm-20mm. After the roller’ s gap is predetermined, the crushing grain size can be controlled reliably, and all of it is discharged from the lower part of the crushing chamber with ideal grain size.

Specification and model | Roll diameter (mm) | Feed size (mm) | Productive capacity (t/h) |

2PGT400×250 | φ400 | ≤25 | 2-10 |

2PGT400×400 | φ400 | ≤25 | 5-12 |

2PGT610×400 | φ610 | ≤30 | 5-20 |

2PGT750×500 | φ750 | ≤30 | 10-40 |

2PGT800×600 | φ800 | ≤40 | 12-50 |

2PGY800×800 | φ800 | ≤40 | 40-50 |

| 2PGY800×1000 | φ800 | ≤40 | 50-80 |

2PGY1000×800 | φ1000 | ≤40 | 50-80 |

2PGY1000×1000 | φ1000 | ≤40 | 80-100 |

2PGY1200×1000 | φ1200 | ≤60 | 100-120 |

2PGY1200×1200 | φ1200 | ≤60 | 120-150 |

2PGY1500×1000 | φ1500 | ≤80 | 150-200 |

2PGY1500×1200 | φ1500 | ≤80 | 200-250 |

2PGY1800×1000 | φ1800 | ≤100 | 250-300 |

2PGY2000×1200 | φ2000 | ≤120 | 300-400 |