Wet Pan Mill

Wet Pan Mill

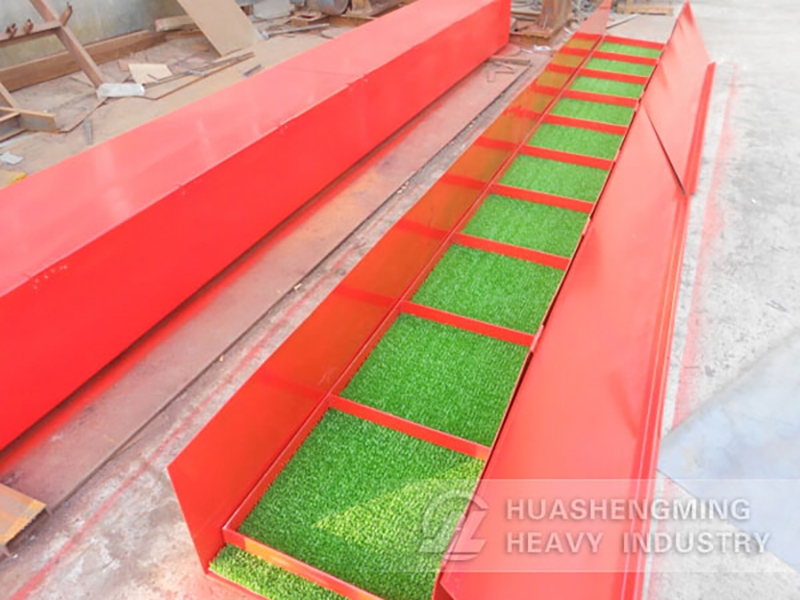

Wet Pan Mill is also called Wet Grinding Machine. Based on the different structure it is divided into double roller grinding and three roller grinding.

- Application:All kinds of ferrous metal, non-ferrous metal, non-metallic minerals, and the separation of gold, silver, lead, iron, copper and so on.

- Max feeding size: 30 mm

- Output size: /

- Capacity:80-150 t/day

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Wet Pan Mill is also called Wet Grinding Machine. Based on the different structure it is divided into double roller grinding and three roller grinding. They are mainly used for grinding operation, such as all kinds of ferrous metal, non-ferrous metal, non-metallic minerals, and the separation of gold, silver, lead, iron, copper and so on.

Wet Pan Mill is the excellent equipment for replacing ball mill, is the first choice of milling equipment for small and medium-sized enterprises.

Features:

1. Easy to install and operate;

2. Very simple structure, only consist the electric motor, transmission, frame, and iron miller;

3. Easy for maintenance and wear well;

4. Low price and low operation cost, high output;

5. Small in size, easy to move and uninstall.

1. Firstly the motor will transmit the motive power to reduction gears,under the drive of reduction gears that passing through large vertical spindle, then the power cabient transfers to above whippletree.

2. The whippletree pulls the two runner wheels clcokwise rotation,runner wheels are not only revoluting around the large vertical spindle but also could retating by themselves.

3. After adding into ore, the materials are under the extrusion of grinding roller weight to revoluting and rotating with runner wheels,when twisting that coming into being huge friction force with grinding base,after suffering repeated extrusion,rub,grinding that be crushed thoroughly.

4. Under the effection of grinding roller operating,the crushed materials and the water mixed intensively to float on it uniformly,then passing through the overflow discharge gate that setting up on the mill basin to discharge,after that enter into next operation procedure to process.

5.Coarse mineral was sank on the bottom of grinding base, going on grinding and crushing,till the fineness could reach to standard floating on it.

Model | Specification | Input size | Rotate Speed | Powder | Weight |

1600A | 1600×400×200×500±20mm | <30mm | 20-22 | 25KW | 14.5 |

1500A | 1500×350×200×460±20mm | 20-22 | 22KW | 13.5 | |

1500B | 1500×350×150×460±20mm | 20-22 | 22KW | 12.3 | |

1500C | 1500×300×150×420±20mm | 20-22 | 22KW | 11.3 | |

1400A | 1400×250×150×350±20mm | 16-18 | 18.5kw | 8.5 | |

1400B | 1400×250×150×350±20mm | 21-23 | 18.5kw | 8.5 | |

1350A | 1350×250×150×350±20mm | 16-18 | 18.5kw | 8 | |

1350B | 1350×250×150×350±20mm | 21-23 | 18.5kw | 8 | |

1300A | 1300×250×150×350±20mm | 16-18 | 15kw | 7.5 | |

1300B | 1300×250×150×350±20mm | 21-23 | 15kw | 7.5 | |

1200A | 1200×200×80×250±20mm | 17-19 | 7.5kw | 5.5 | |

1200B | 1200×200×80×250±20mm | 23-25 | 7.5kw | 5.5 | |

1100A | 1100×200×80×250±20mm | 17-19 | 7.5kw | 5 | |

1100B | 1100×200×80×250±20mm | 23-25 | 7.5kw | 5 | |

1000 | 1000×200×80×250±20mm | 13-15 | 5.5kw | 4.5 |