Linear Vibrating Screen

Linear Vibrating Screen

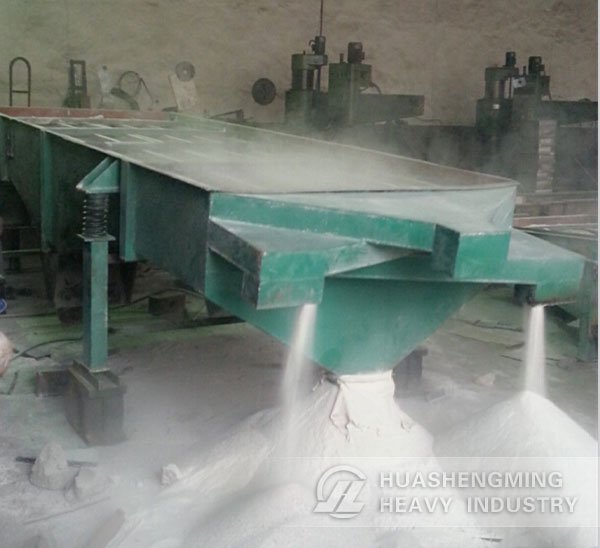

Linear Vibrating Screen is used to select and classify powder and granular materials, and is widely used in plastics, abrasives, chemicals, medicine, building materials, food, carbon, fertilizer and other industries.

- Application:Select and classify powder and granular materials, and is widely used in plastics, abrasives, chemicals, medicine, building materials, food, carbon, fertilizer and other industries.

- Max feeding size: 300 mm

- Output size: 0-100 mm

- Capacity:10-600 t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Linear Vibrating Screen is used to select and classify powder and granular materials, and is widely used in plastics, abrasives, chemicals, medicine, building materials, food, carbon, fertilizer and other industries.

Features:

1. Small volume, Light-weight,sample structure , easy installation and maintenance;

2. Low noise and power consumption, High efficiency and low price;

3. Screening high precision, it can screen to 200mesh / 0.074mm;

4. Can replace to variety screen mesh, and with long lifespan;

5. Good sealing sieve machine and powder less float;

6. Impurity and coarse material automatic discharge and working continually;

7. Screen box have wood and steel type, more selection.

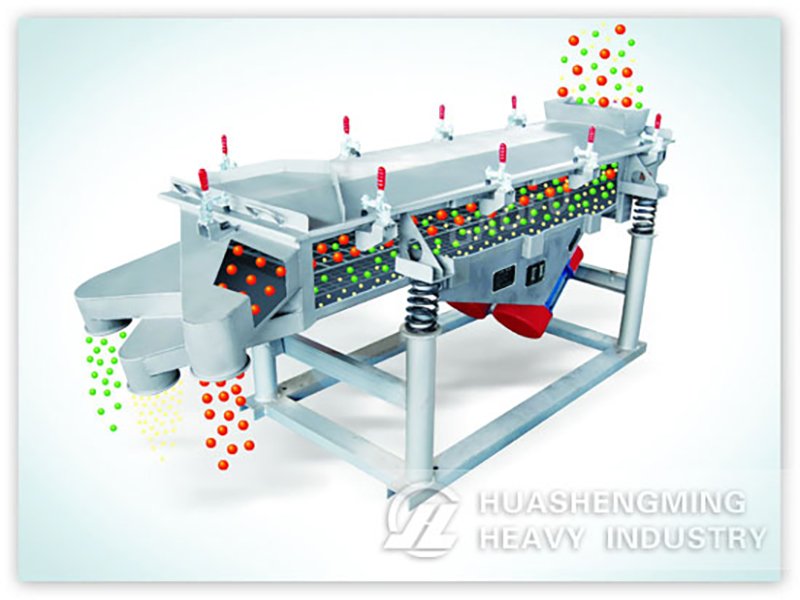

Linear Vibrating Screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Through the flexible coupling, the motor drives the eccentric block of the vibrator at high rotary speed, generating the centrifugal force, and then lead the screen box to do circular movement by the amplitude. After that, the materials in the slope screen surface will be cast continuously by the force generated from the screen box, then realize the purpose of classifying.

Model | Sieve specifi- | Sieve | Mesh | Feeding | Proce ssing | Motor | Total | Vibra tion | Double | Obli quity | Dimensions |

(L*W)(mm) | Layer | mm | mm | (t/h) | kw | kg | (Hz) | (mm) | ℃ | (L*W*H)(mm) | |

ZSG1237 | 3700*1200 | 1 | 4-50 | <=200 | 10-100 | 5.5*2 | 2250 | 16 | 6-8 | 15 | 3800*2050*1920 |

2ZSG1237 | 3700*1200 | 2 | 4-50 | <=200 | 10-100 | 5.5*2 | 3345 | 16 | 6-8 | 15 | 3800*2050*2200 |

ZSG1443 | 4300*1400 | 1 | 4-50 | <=200 | 10-150 | 5.5*2 | 4100 | 16 | 6-8 | 15 | 4500*3040*2500 |

2ZSG1443 | 4300*1400 | 2 | 4-50 | <=200 | 10-150 | 5.5*2 | 4900 | 16 | 6-8 | 15 | 4500*3040*2700 |

3ZSG1443 | 4300*1400 | 3 | 4-50 | <=200 | 10-150 | 5.5*2 | 5870 | 16 | 6-8 | 15 | 4500*3040*2820 |

2ZSG1548 | 4800*1500 | 2 | 5-50 | <=200 | 15-200 | 7.5*2 | 5836 | 16 | 8-10 | 15 | 4800*3140*2814 |

3ZSG1548 | 4800*1500 | 3 | 5-50 | <=200 | 15-200 | 7.5*2 | 6900 | 16 | 8-10 | 15 | 4799*3140*3014 |

2ZSG1848 | 4800*1800 | 2 | 5-50 | <=300 | 50-500 | 7.5*2 | 6489 | 16 | 8-10 | 15 | 4799*3440*2814 |

3ZSG1848 | 4800*1800 | 3 | 5-50 | <=300 | 50-500 | 7.5*2 | 7750 | 16 | 8-10 | 15 | 4799*3440*3014 |

4ZSG1848 | 4800*1800 | 4 | 5-50 | <=200 | 50-500 | 11*2 | 8300 | 16 | 8-10 | 15 | 4799*3440*3503 |

2ZSG1860 | 6000*1800 | 2 | 5-150 | <=300 | 80-600 | 11*2 | 9950 | 16 | 8-10 | 15 | 6000*3440*3326 |