Magnetic Separator

Magnetic Separator

Magnetic separator can be used for wet dressing of the following ores with the sizes less than 3mm, which are magnetite, pyrrhotine, calcined ore, limetite and so on

- Application:Magnetite, magnetic pyrite, roasted ore, titanic iron ore, hematite, limonite, siderite, wolframite, tantalum-niobium ore, red mud, quartz, fluorite and feldspar etc.

- Max feeding size: 0-3 mm

- Output size: 0-3 mm

- Capacity:10-280 t/h

- Delivery:5-15 days

- Shipment:Accept EXW, FOB and CIF terms, by sea or by train. we have 20 years cooperate transport company. best freight, fast delivery.

Application:

Magnetic separator can be used for wet dressing of the following ores with the sizes less than 3mm, which are magnetite, pyrrhotine, calcined ore, limetite and so on. It also can be used to remove the iron for processing of coal, non-metalic mineral and construction materials. magnetic separator has played an important role in the industry of lumbering, beneficiation, ceramics, chemical, food and so on .

HSM can provide magnetic separator of forward flow, semi counter flow and counter flow types as customers’ requirements. We can provide magnetic separators of forward flow, semi counter flow and counter flow types as customers’ requirements.

Features:

1. Simple structure;

2. Easy-open structure gives a convenient cleaning;

3. Large handling, Low power;

5. Easy to operate and maintain;

6. The number of axial magnetic can be adjusted in accordance with material characteristics;

7. This magnetic separator is suitable for processing various bulk materials and will not blocked for its compact structure.

8. Also has disaggregating function for sticky and poor-fluidity powders;

9. Stainless steel machine and full-closed operation enable an easy clean;

10. This high gradient magnetic separator has optimized magnetic circuit, which offers high intensity magnetic field for better separating effect;

11. Magnetic separator working under high temperature.

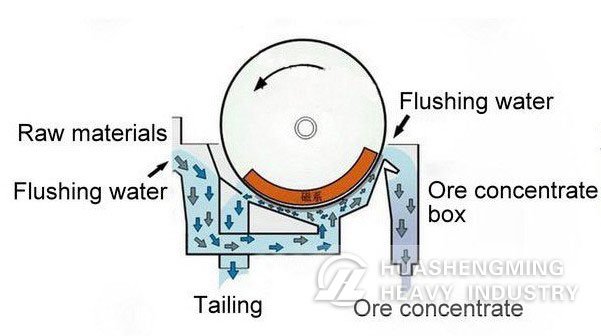

Slurry enters chute through ore tank, and then gets into separating zone by waterpower. Minerals with strong magnetism is absorbed on the barrel’s surface under the force of magnetic field and get into the ore concentrate outlet along with the rotation of cylinder. After leaving the magnetic field, they flow into ore concentrate box by the action of gravity and flushing water. Gangue and ore with weak magnetism are discharged into a pipe in the opposite direction of cylinder rotation.

Model | Shell diameter | Shell length | Shell rotation speed | Feeding size | Processing capacity | Power |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |