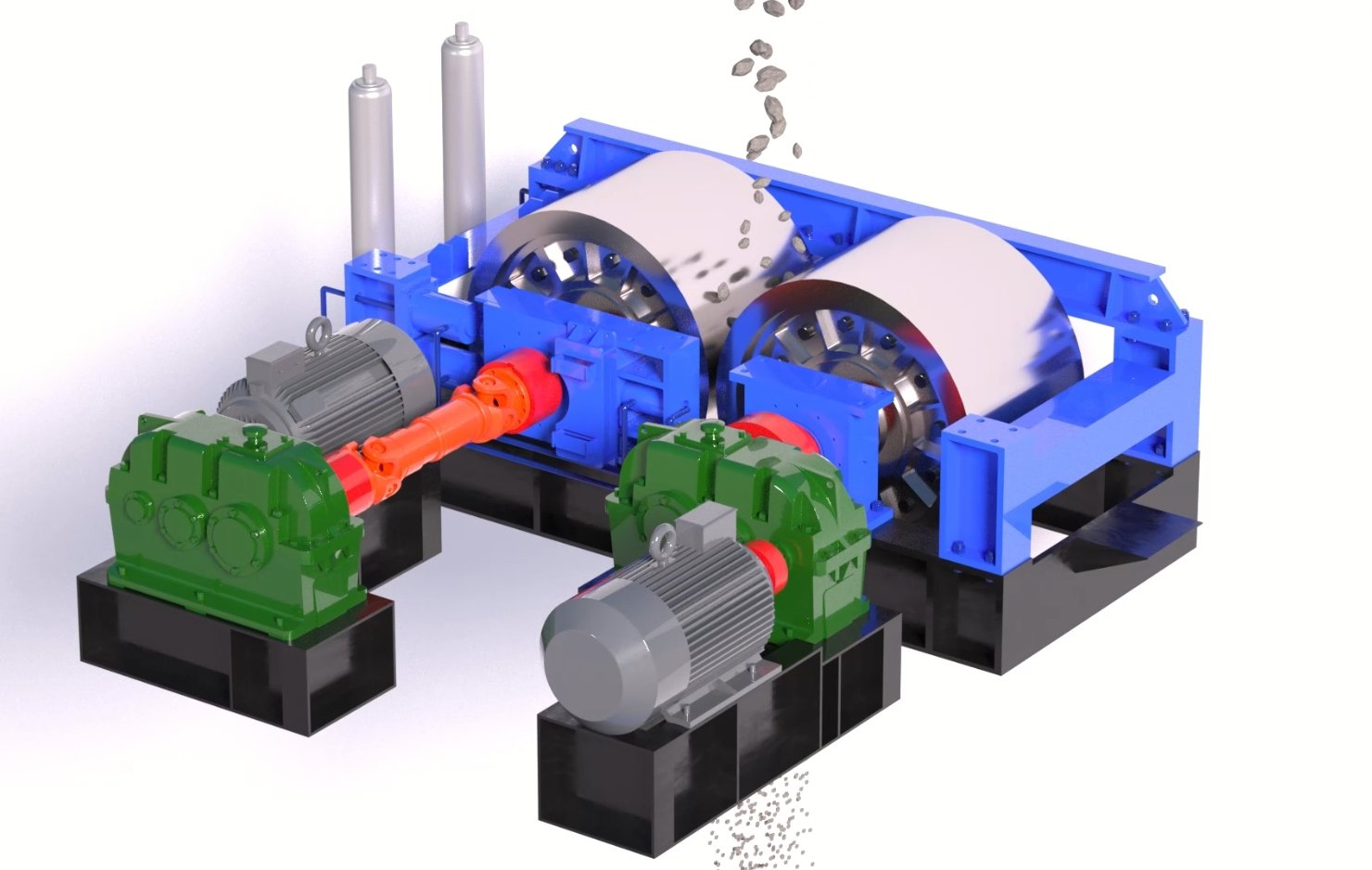

The 1210 hydraulic roller sand making machine is suitable for processing a variety of medium hardness and below stones, including limestone, river pebbles, granite, basalt, coal gangue, iron ore, quartz stone, etc. Whether it is natural stone or industrial waste, the equipment can easily handle it, ensuring that the output particle size is uniform and high quality. Its wide range of applications makes the 1210 hydraulic roller sand making machine an ideal equipment for many stone factories and construction sites.

The hydraulic roller sand making machine has the following significant advantages when processing stone:

High efficiency and energy saving: Using advanced transmission system and optimized design, it has low energy consumption and high production efficiency.

Wear-resistant and durable: The rollers and wearing parts are made of high-strength wear-resistant materials, with long service life and low maintenance costs.

Uniform discharging particle size: through precise gap adjustment, the discharging particle size is ensured to be uniform and meet high standard requirements.

Good environmental performance: The sealed crushing chamber and efficient dust removal system effectively reduce noise and dust emissions, complying with environmental standards.

Easy to operate: Equipped with an intelligent control system, friendly operation interface and easy maintenance.

Strong adaptability: suitable for a variety of materials with medium hardness and below, widely used in stone factories, construction sites and other fields.

High reliability: Strict quality control and testing ensure that the equipment operates stably under various working conditions.

High degree of automation: fully automated operation can be achieved, reducing manual intervention and improving production efficiency.

Convenient maintenance: Modular design makes maintenance and inspection more convenient and faster, reducing downtime.

High cost-effectiveness: Since there is almost no need to replace wearing parts frequently, maintenance costs are significantly reduced and long-term operating costs are lower.

Hydraulic adjustment system: The hydraulic system can quickly and accurately adjust the roller gap to ensure the consistency and stability of the discharge particle size.

High safety: The hydraulic system has an overload protection function. When encountering hard objects or foreign objects, it can automatically adjust the pressure to protect the equipment from damage.