As demand for sand and gravel continues to grow, the need for more efficient and cost-effective production methods becomes even more urgent. Companies in the construction and mining industries are increasingly turning to advanced equipment, such as the CNC Roller Press, to streamline their operations. This innovative technology offers precise control, improved throughput, and energy savings, making it an ideal solution for sand and gravel production.

What is a CNC Roller Press?

A CNC Roller Press is a highly efficient and precise crushing machine that utilizes Computer Numerical Control (CNC) technology. The CNC system allows for fine-tuned adjustments to roller pressure, enabling consistent output and enhanced performance. This results in energy savings, reduced wear on machinery, and higher production capacity.

Key Features and Benefits

Precise Control: The CNC technology allows for exact adjustments to crushing force, ensuring that the sand and gravel produced meet quality standards.

Energy Efficiency: With less energy consumption compared to traditional crushers, the CNC roller press helps reduce operating costs.

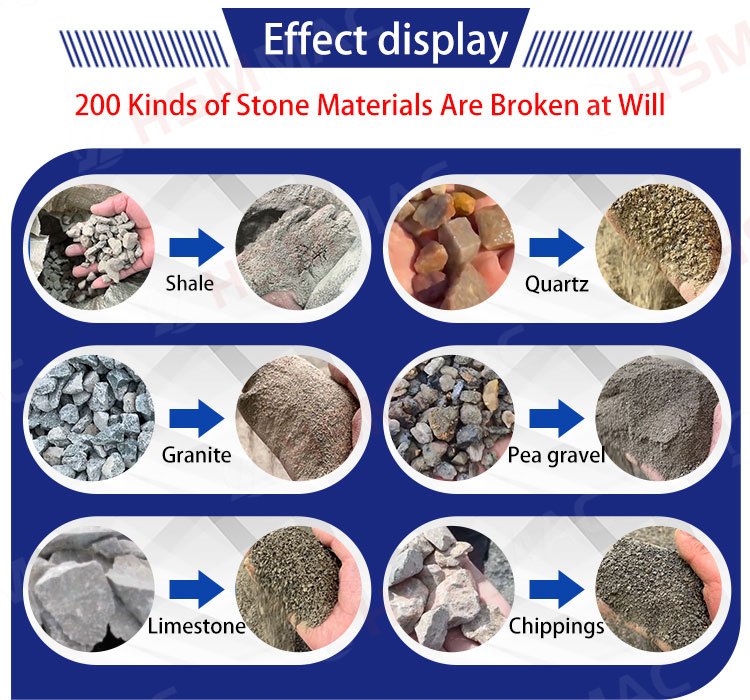

Versatility: The CNC roller press can handle a wide variety of raw materials, including different types of sand and gravel, making it a versatile choice for many production lines.

Durability: Built with high-quality components, the CNC roller press is designed to handle heavy workloads, ensuring long-term reliability with minimal maintenance.

Double Roller Crusher Models: Finding the Right Fit

When considering the right crusher for your sand and gravel production needs, it's important to choose a model that fits your production requirements. Double roller crushers come in various sizes to accommodate different production scales. Here are the categories based on different models:

Small spring roller crushers, such as 2PGT400×250, 2PGT400×400, and 2PGT610×400, produce an hourly output of about 2-20 tons. These models are ideal for small and medium-sized sand plants, offering an excellent solution for businesses with lower capacity needs.

Medium-sized spring roller crushers, including 2PGT750×500 and 2PGT800×600, produce an hourly output of 10-50 tons. These models are suitable for companies that need a moderate level of production and are commonly used in medium-sized plants.

Medium-sized hydraulic double roller crushers, such as 2PGY750×500, 2PGY800×600, 2PGY800×800, and 2PGY1000×800, offer an output of 20-80 tons per hour. The hydraulic models offer higher intelligence, greater efficiency, and lower operational costs.

Large CNC hydraulic double roller crushers, such as 2PGY1000×1000, 2PGY1200×1200, 2PGY1500×1000, 2PGY1800×1000, and 2PGY2000×1000, produce an hourly output of 80-400 tons. These large models are perfect for medium and large sand plants, offering high capacity and advanced features.

Conclusion

Choosing the right equipment is crucial for optimizing production and reducing costs. The CNC Roller Press is an excellent choice for sand and gravel producers looking to enhance efficiency, reduce energy consumption, and improve the quality of their products. Whether you need a small, medium, or large-scale crusher, the variety of double roller crushers available ensures that you can find a solution that fits your specific needs.